PVDF Nanofiber Membranes for Dissolved Methane Recovery from Water Prepared by Combining Electrospinning and Hot-Pressing Methods

- Autors: Montero-Rocca, F. ; Badia-Valiente, J.D. ; Jiménez-Robles, R. ; Martínez-Soria, V ; Izquierdo, M.

- Lloc de realització, Editorial, Any: València , 2025.

- Tipus de publicació: Article

- URL Publicacio: PVDF Nanofiber Membranes for Dissolved Methane Recovery from Water Prepared by Combining Electrospinning and Hot-Pressing Methods

- Titol publicació (nom del llibre o de la revista): ACS Polymers Au. Num.5(4)

-

Resum:

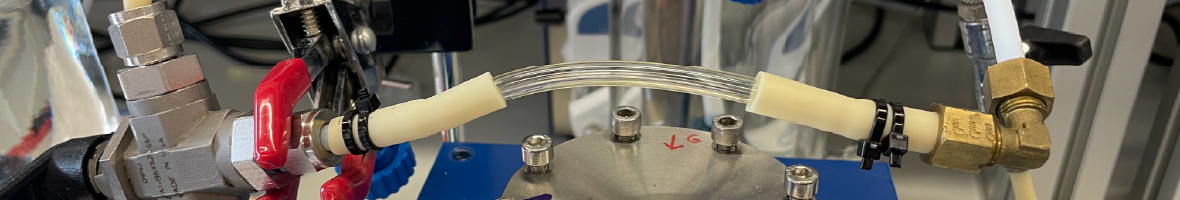

Polyvinylidene fluoride (PVDF) electrospun nanofiber membranes (ENMs) could potentially be used in membrane contactors (MCs) for environmental applications, such as the removal of dissolved CH4 from anaerobic effluents. In this work, a PVDF flat-sheet ENM fabrication protocol, including the electrospinning processing and the subsequent hot-pressing treatment (HP), has been developed to produce hydrophobic membranes with suitable integrity and pore size distribution for gas–liquid separations in MCs. The HP study explored the effects of pressure (1, 10, and 20 MPa), temperature (25, 60, 80, and 120 °C), and time (2, 4, 6, and 10 min) on the morphological properties and hydrophobicity of the membranes. Our research revealed that fibers in the PVDF ENMs began to sinter at temperatures above 60 °C when hot-pressed between 1 and 20 MPa. ENM samples were prepared at different dope compositions (10–15% PVDF, 0.00–0.043% LiCl). After HP (≥1 MPa, ≥60 °C, and 6 min), the membrane thickness and water contact angle (WCA) decreased considerably, and lower pore sizes with narrower distributions were obtained. At higher pressure (10 MPa), a noticeable decrease in thickness (from 270 to 38 μm) and WCA (from 139 to 110°) was observed. Additionally, pore size distribution shifted toward a predominant narrow peak of around 0.40 μm. HP enhanced the uniformity of the PVDF crystalline structure without altering its overall crystallinity degree (40–42%). The HP ENM exhibited a comparable dissolved CH4 recovery performance to a commercial PVDF membrane and demonstrated sufficient mechanical integrity to endure operating conditions, maintaining a stable performance for at least 80 h.

ISSN: 2694-2453