-

Evaluation of liquid effluents from an urban wastewater treatment plant as CO2 absorbents in a membrane-based biogas upgrading system in an operational environment

Jiménez-Robles, R., Martínez-Soria, V., Hervás-Martínez, R., Montoya, T., Sempere, F., & Izquierdo, M.

València , 2025. ArticleJournal of Water Process Engineering. Num.79

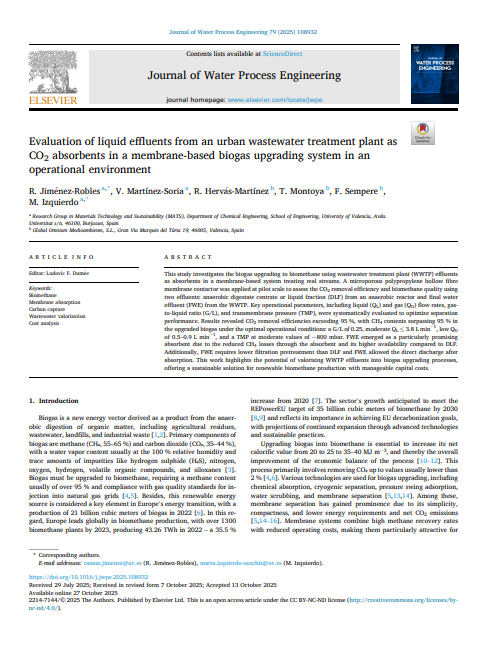

This study investigates the biogas upgrading to biomethane using wastewater treatment plant (WWTP) effluents as absorbents in a membrane-based system treating real streams. A microporous polypropylene hollow fibre membrane contactor was applied at pilot scale to assess the CO2 removal efficiency and biomethane quality using two effluents: anaerobic digestate centrate or liquid fraction (DLF) from an anaerobic reactor and final water effluent (FWE) from the WWTP. Key operational parameters, including liquid (QL) and gas (QG) flow rates, gas-to-liquid ratio (G/L), and transmembrane pressure (TMP), were systematically evaluated to optimize separation performance. Results revealed CO2 removal...

This study investigates the biogas upgrading to biomethane using wastewater treatment plant (WWTP) effluents as absorbents in a membrane-based system treating real streams. A microporous polypropylene hollow fibre membrane contactor was applied at pilot scale to assess the CO2 removal efficiency and biomethane quality using two effluents: anaerobic digestate centrate or liquid fraction (DLF) from an anaerobic reactor and final water effluent (FWE) from the WWTP. Key operational parameters, including liquid (QL) and gas (QG) flow rates, gas-to-liquid ratio (G/L), and transmembrane pressure (TMP), were systematically evaluated to optimize separation performance. Results revealed CO2 removal efficiencies exceeding 95 %, with CH4 contents surpassing 95 % in the upgraded biogas under the optimal operational conditions: a G/L of 0.25, moderate QL ≤ 3.8 L min−1, low QG of 0.5–0.9 L min−1, and a TMP at moderate values of ∼800 mbar. FWE emerged as a particularly promising absorbent due to the reduced CH4 losses through the absorbent and its higher availability compared to DLF. Additionally, FWE requires lower filtration pretreatment than DLF and FWE allowed the direct discharge after absorption. This work highlights the potential of valorising WWTP effluents into biogas upgrading processes, offering a sustainable solution for renewable biomethane production with manageable capital costs.

Llegir més Ocultar -

PVDF Nanofiber Membranes for Dissolved Methane Recovery from Water Prepared by Combining Electrospinning and Hot-Pressing Methods

Montero-Rocca, F. ; Badia-Valiente, J.D. ; Jiménez-Robles, R. ; Martínez-Soria, V ; Izquierdo, M.

València , 2025. ArticleACS Polymers Au. Num.5(4)

Polyvinylidene fluoride (PVDF) electrospun nanofiber membranes (ENMs) could potentially be used in membrane contactors (MCs) for environmental applications, such as the removal of dissolved CH4 from anaerobic effluents. In this work, a PVDF flat-sheet ENM fabrication protocol, including the electrospinning processing and the subsequent hot-pressing treatment (HP), has been developed to produce hydrophobic membranes with suitable integrity and pore size distribution for gas–liquid separations in MCs. The HP study explored the effects of pressure (1, 10, and 20 MPa), temperature (25, 60, 80, and 120 °C), and time (2, 4, 6, and 10 min) on the morphological properties and hydrophobicity of the...

Polyvinylidene fluoride (PVDF) electrospun nanofiber membranes (ENMs) could potentially be used in membrane contactors (MCs) for environmental applications, such as the removal of dissolved CH4 from anaerobic effluents. In this work, a PVDF flat-sheet ENM fabrication protocol, including the electrospinning processing and the subsequent hot-pressing treatment (HP), has been developed to produce hydrophobic membranes with suitable integrity and pore size distribution for gas–liquid separations in MCs. The HP study explored the effects of pressure (1, 10, and 20 MPa), temperature (25, 60, 80, and 120 °C), and time (2, 4, 6, and 10 min) on the morphological properties and hydrophobicity of the membranes. Our research revealed that fibers in the PVDF ENMs began to sinter at temperatures above 60 °C when hot-pressed between 1 and 20 MPa. ENM samples were prepared at different dope compositions (10–15% PVDF, 0.00–0.043% LiCl). After HP (≥1 MPa, ≥60 °C, and 6 min), the membrane thickness and water contact angle (WCA) decreased considerably, and lower pore sizes with narrower distributions were obtained. At higher pressure (10 MPa), a noticeable decrease in thickness (from 270 to 38 μm) and WCA (from 139 to 110°) was observed. Additionally, pore size distribution shifted toward a predominant narrow peak of around 0.40 μm. HP enhanced the uniformity of the PVDF crystalline structure without altering its overall crystallinity degree (40–42%). The HP ENM exhibited a comparable dissolved CH4 recovery performance to a commercial PVDF membrane and demonstrated sufficient mechanical integrity to endure operating conditions, maintaining a stable performance for at least 80 h.

Llegir més Ocultar ISSN: 2694-2453 -

Hydrophobic PVDF-Based Electrospun NanofibrousMembranes: Design Criteria Fabrication and Resistance toLong-Term Hydrodynamic Operation

Montero-Rocca, F. ; Badia-Valiente, J.D. ; Gil-Castell, O ; Jiménez-Robles, R. ; Martínez-Soria, V ; Izquierdo, M.

València , 2025. ArticleJournal of Applied Polymer Science. Num.142(41)

The mechanical integrity of electrospun nanofiber membranes (ENMs) under operational conditions may limit their appli-cation in membrane contactors. This study integrated the electrospinning (ESP) with heat treatments to enhance nanofiberintegrity in polyvinylidene fluoride (PVDF) ENMs. The impact of ESP parameters on the properties of the resulting ENMswas explored, including polymer dope flow rate (1.0–1.2 mL h−1), tip-to- collector distance (TCD, 12–18 cm), and needle size(20–22 Ga), along with collector type (flat or rotary drum), needle motion (static or moving at 10 cm s−1), and collector rotationspeed were assessed. Heat treatment was evaluated at 130°C–170°C for 1–15 h. The...

The mechanical integrity of electrospun nanofiber membranes (ENMs) under operational conditions may limit their appli-cation in membrane contactors. This study integrated the electrospinning (ESP) with heat treatments to enhance nanofiberintegrity in polyvinylidene fluoride (PVDF) ENMs. The impact of ESP parameters on the properties of the resulting ENMswas explored, including polymer dope flow rate (1.0–1.2 mL h−1), tip-to- collector distance (TCD, 12–18 cm), and needle size(20–22 Ga), along with collector type (flat or rotary drum), needle motion (static or moving at 10 cm s−1), and collector rotationspeed were assessed. Heat treatment was evaluated at 130°C–170°C for 1–15 h. The optimized ENM exhibited a 134° ± 5°water contact angle, 200 ± 50 μm thickness, and 3.10 ± 0.02 mg cm−2 surface density. It was fabricated using a 1.20 mL h−1polymer dope flow rate, 12 cm TCD, and a static 20 Ga needle during an 8-h ESP session with a rotary collector, followed bytreatment at 150°C under 70 Pa for 6 h. It endured over 800 h under high hydraulic stress (21 L h−1 water flow), outperforminga commercial PVDF membrane and highlighting its potential for long-term operation in gas–liquid membrane contactorapplications.

Llegir més Ocultar ISSN: 1097-4628 -

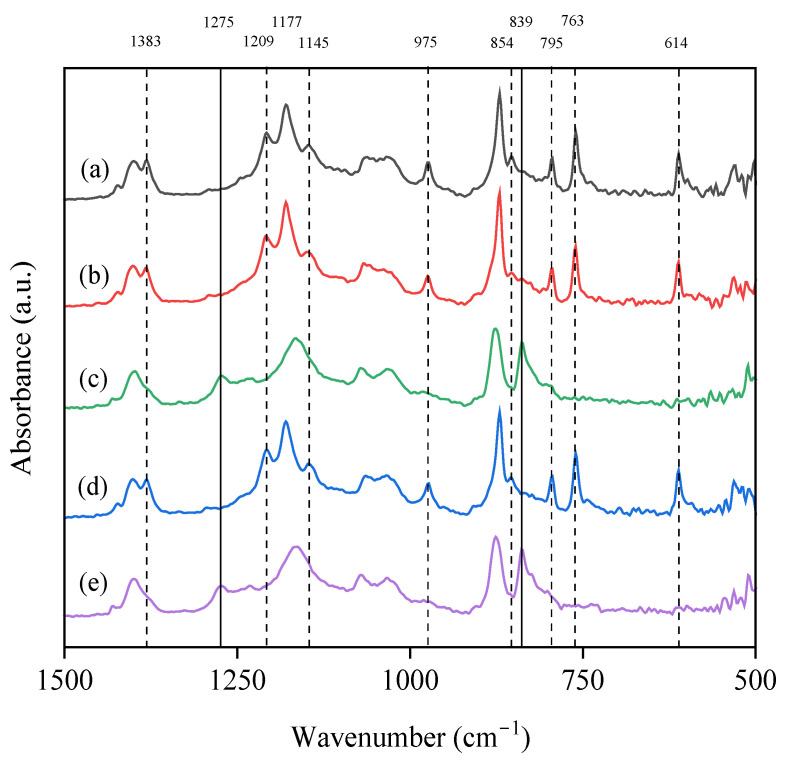

UV-C and UV-C/H₂O-Induced Abiotic Degradation of Films of Commercial PBAT/TPS Blends

K. Gutiérrez-Silva ; A. Jordán-Silvestre ; A. Cháfer ; R. Muñoz-Espí ; O. Gil-Castell ; J.D. Badia

València , 2025. ArticlePolymers. Num.17(9)

The environmental impact of conventional plastics has spurred interest in biopolymers as sustainable alternatives, yet their performance under abiotic degradation conditions still remain unclear. This study investigated the effects of ultraviolet C (UV-C) irradiation and its combination with water immersion (UV-C/H2O) on films of commercial poly(butylene adipate-co-terephthalate)-thermoplastic starch (PBAT/TPS) blends. Changes in structural, chemical, morphological, and thermal properties, as well as molar mass, were analyzed. The results showed distinct degradation mechanisms during exposure to UV-C irradiation either in dry or during water-immersion conditions. UV-C irradiation disrupted...

The environmental impact of conventional plastics has spurred interest in biopolymers as sustainable alternatives, yet their performance under abiotic degradation conditions still remain unclear. This study investigated the effects of ultraviolet C (UV-C) irradiation and its combination with water immersion (UV-C/H2O) on films of commercial poly(butylene adipate-co-terephthalate)-thermoplastic starch (PBAT/TPS) blends. Changes in structural, chemical, morphological, and thermal properties, as well as molar mass, were analyzed. The results showed distinct degradation mechanisms during exposure to UV-C irradiation either in dry or during water-immersion conditions. UV-C irradiation disrupted PBAT ester linkages, inducing photodegradation and chain scission, leading to a more pronounced molar mass decrease compared to that under water immersion, where a more restrained impact on the molar mass was ascribed to diffuse attenuation coefficient of irradiation. Nevertheless, under UV-C/H2O conditions, erosion and disintegration were enhanced by dissolving and leaching of mainly the TPS fraction, creating a porous structure that facilitated the degradation of the film. Blends with higher TPS content exhibited greater susceptibility, with pronounced reductions in PBAT molar mass. In conclusion, exposure of films of PBAT/TPS blends to ultraviolet/water-assisted environments effectively initiated abiotic degradation, in which fragmentation was accentuated by the contribution of water immersion.

Llegir més Ocultar ISSN: 2073-4360 -

Effect of Choline Chloride-Based DES on the Pore-Forming Ability and Properties of PVDF Membranes Prepared with Triethyl Phosphate as Green Solvent

Alejando Gálvez-Subiela, Ramón Jiménez-Robles, José David Badia, Marta Izquierdo, Amparo Chafer.

(2025). ArticlePolymers (Basel). Num.17(7), 984.

Superhydrophobic poly(vinylidene fluoride) (PVDF) membranes were obtained by a surface treatment consisting of oxygen plasma activation followed by functionalisation with a mixture of silica precursor (SiP) (tetraethyl-orthosilicate [TEOS] or 3-(triethoxysilyl)-propylamine [APTES]) and a fluoroalkylsilane (1H,1H,2H,2H-perfluorooctyltriethoxysilane), and were benchmarked with coated membranes without plasma activation. The modifications acted mainly on the suThis study explores the influence of various additives on the morphological, chemical, and thermal properties of poly(vinylidene fluoride) (PVDF) membranes prepared via the non-solvent induced phase separation (NIPS) technique. The use...

Superhydrophobic poly(vinylidene fluoride) (PVDF) membranes were obtained by a surface treatment consisting of oxygen plasma activation followed by functionalisation with a mixture of silica precursor (SiP) (tetraethyl-orthosilicate [TEOS] or 3-(triethoxysilyl)-propylamine [APTES]) and a fluoroalkylsilane (1H,1H,2H,2H-perfluorooctyltriethoxysilane), and were benchmarked with coated membranes without plasma activation. The modifications acted mainly on the suThis study explores the influence of various additives on the morphological, chemical, and thermal properties of poly(vinylidene fluoride) (PVDF) membranes prepared via the non-solvent induced phase separation (NIPS) technique. The use of a green solvent such as triethyl phosphate (TEP) was shown to be successful. A particular focus was dedicated to pore formers based on choline chloride-based deep eutectic solvents (DES) in combination with ethylene glycol and glycerol, i.e., ChCl/EG and ChCl/GLY, and its benchmark with traditional counterparts such as poly(ethylene glycol) (PEG) and glycerol (GLY). Comprehensive characterization was conducted using FESEM, FTIR, XRD, and DSC techniques to evaluate changes in membrane morphology, porosity, and crystallinity. PEG acted as a pore-forming agent, transitioning the internal structure from spherulitic to sponge-like with consistent pore sizes, while GLY produced a nodular morphology at higher concentrations due to increased dope solution viscosity. DES induced significant shifts in crystalline phase composition, decreasing α-phase fractions and promoting β-phase formation at higher concentrations. While the overall porosity remained unaffected by the addition of GLY or PEG, it was dependent on the DES concentration in the dope at lower values than those obtained by GLY and PEG. Membrane pore size with ChCl/GLY was lower than with ChCl/EG and GLY. All membranes showed performance at the hydrophobic regime. The findings demonstrate that ChCl/EG and ChCl/GLY can tailor the structural and thermal properties of TEP-driven PVDF membranes, providing a green and versatile approach to customize the membrane properties for specific applications.

Llegir més OcultarKeywords: choline chloride; deep eutectic solvent (DES); glycerol; green solvent; membrane; non-solvent induced phase separation (NIPS); poly(vinylidene fluoride) PVDF; polyethylene glycol (PEG); triethyl phosphate (TEP).

Gálvez-Subiela, A., Jiménez-Robles, R., Badia-Valiente, J. D., Izquierdo, M., & Chafer, A. (2025). Effect of Choline Chloride-Based DES on the Pore-Forming Ability and Properties of PVDF Membranes Prepared with Triethyl Phosphate as Green Solvent. Polymers, 17(7), 984. https://doi.org/10.3390/polym17070984

[Llegir més] [Ocultar] DOI: 10.3390/polym17070984 -

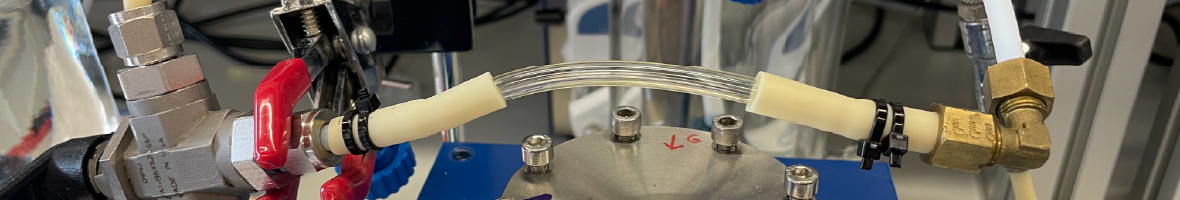

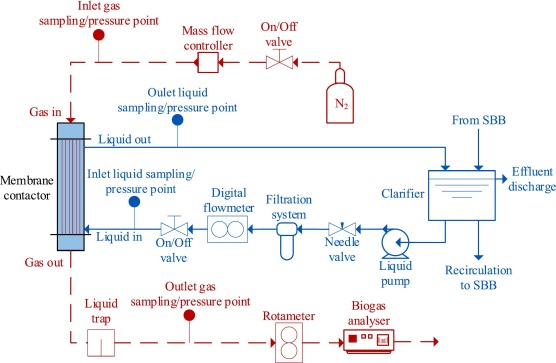

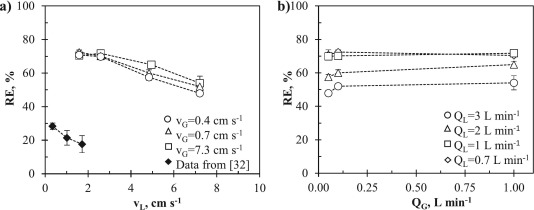

Membrane contactor performance for the dissolved methane recovery from the liquid effluent of a desulphurisation reactor for biogas purification: Evaluation of operating conditions, fouling and cleaning strategies

R. Jiménez-Robles, M. Izquierdo, V. Martínez-Soria, R. Hervás-Martínez, T. Montoya, F. Sempere.

(2025). ArticleJournal of Water Process Engineering. Num.Volume 71, March 2025, 107210.

Membrane contactors offer a promising feasible alternative to conventional desorption units due to their higher surface-to-volume ratio and operational flexibility. In this regard, a hollow fibre membrane contactor (HFMC) was coupled to a biogas desulphurisation reactor at pilot scale to recover the dissolved CH4 (D-CH4) present in the liquid effluent. To determine the effects of the operational parameters in the separation efficiency, different liquid (QL = 0.7–3 L min−1) and sweep gas flow rates (QG = 0.05–1 L min−1) were tested using a polypropylene HFMC. The D-CH4 removal efficiency (RE) was strongly dependent on the QL with a negligible effect of the QG, since the liquid phase boundary...

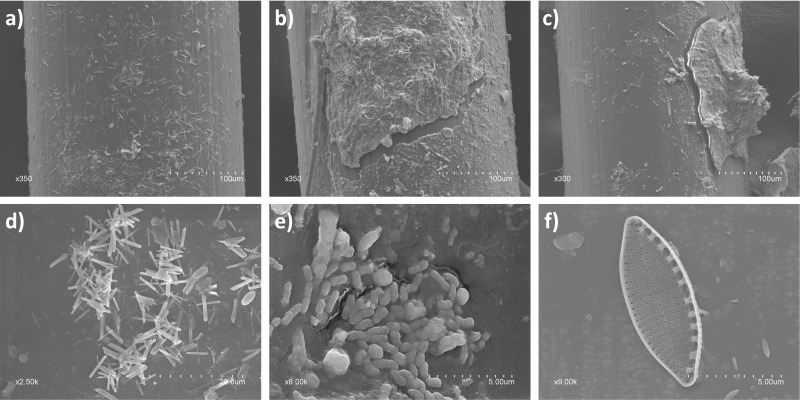

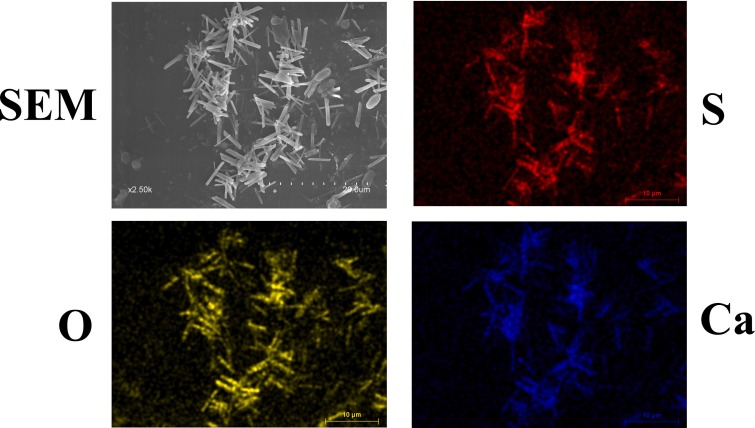

Membrane contactors offer a promising feasible alternative to conventional desorption units due to their higher surface-to-volume ratio and operational flexibility. In this regard, a hollow fibre membrane contactor (HFMC) was coupled to a biogas desulphurisation reactor at pilot scale to recover the dissolved CH4 (D-CH4) present in the liquid effluent. To determine the effects of the operational parameters in the separation efficiency, different liquid (QL = 0.7–3 L min−1) and sweep gas flow rates (QG = 0.05–1 L min−1) were tested using a polypropylene HFMC. The D-CH4 removal efficiency (RE) was strongly dependent on the QL with a negligible effect of the QG, since the liquid phase boundary layer governed the mass transport. Thus, REs up to 70 % were obtained at QL ≤ 1 L min−1 feeding the liquid through the shell side. On the contrary, the CH4 content in the recovered gas was always quite low (<20 %) due to the sweep gas dilution effect and the simultaneous desorption of CO2. In log-term operation, a considerable loss of efficiency was observed when fouling appeared, therefore, different physical and chemical cleaning strategies were investigated. The permanent decline in the RE suggested a significant amount of irreversible fouling which hindered the cleaning efficiency, denoting the need of preventive cleanings. The analysis of the fibre surface elucidated an organic dense fouling cake, biofouling from bacteria and algae, and anhydrite scaling (CaSO4). Importantly, this study demonstrated that this process is an attractive prospect to avoid diffuse emissions and recover an energy vector.

Llegir més OcultarKeywords: Dissolved CH4 recovery, Hollow fibre membrane contactor, Pilot scale operation, Membrane fouling and cleaning, Long-term stability.

Referencia:

R. Jiménez-Robles, M. Izquierdo, V. Martínez-Soria, R. Hervás-Martínez, T. Montoya, F. Sempere. Membrane contactor performance for the dissolved methane recovery from the liquid effluent of a desulphurisation reactor for biogas purification: Evaluation of operating conditions, fouling and cleaning strategies. Journal of Water Process Engineering, 71,2025, 107210

[Llegir més] [Ocultar] DOI: 10.1016/j.jwpe.2025.107210 -

Influence of Vinyl Acetate-Based and Epoxy-Based Compatibilizers on the Design of TPS/PBAT and TPS/PBAT/PBSA Films

Cristina Martín-Poyo ; Josep P. Cerisuelo-Ferriols ; Jose D. Badia-Valiente

València , 2025. ArticleApplied Sciences. Num.15(1)

The study investigated the effect of Vinnex® (vinyl acetate polymer) and Joncryl® (epoxy-based copolymer) as compatibilizers on the mechanical properties of thermoplastic starch (TPS) and polybutylene adipate-co-terephthalate (PBAT) and polybutylene succinate-co-adipate (PBSA) films. Due to TPS’s hydrophilicity and brittleness, blending it with biodegradable polyesters like PBAT enhances its properties but may introduce compatibility challenges. This research evaluated three formulations (TPS/PBAT with Vinnex, TPS/PBAT with Joncryl, and TPS/PBAT with both additives) along with the inclusion of a polybutadiene succinate-co-adipate (PBSA) matrix to further improve performance. Mechanical...

The study investigated the effect of Vinnex® (vinyl acetate polymer) and Joncryl® (epoxy-based copolymer) as compatibilizers on the mechanical properties of thermoplastic starch (TPS) and polybutylene adipate-co-terephthalate (PBAT) and polybutylene succinate-co-adipate (PBSA) films. Due to TPS’s hydrophilicity and brittleness, blending it with biodegradable polyesters like PBAT enhances its properties but may introduce compatibility challenges. This research evaluated three formulations (TPS/PBAT with Vinnex, TPS/PBAT with Joncryl, and TPS/PBAT with both additives) along with the inclusion of a polybutadiene succinate-co-adipate (PBSA) matrix to further improve performance. Mechanical testing (tensile strength, elongation at break, Young’s modulus) reveals that Vinnex and Joncryl enhance plasticization and polymer compatibility, positively impacting TPS/PBAT’s mechanical properties. The introduction of the PBSA matrix further improves tensile strength and elongation. Scanning electron microscopy (SEM) confirms better additive dispersion and interfacial adhesion within the blend. Complementary analysis includes melt flow index, melt density, DSC, and TGA, providing a comprehensive understanding of how these additives optimize TPS/PBAT compounds for sustainable applications. Mechanically, the compatibilized blends showed improved performance: Vinnex mainly enhanced stiffness, Joncryl primarily improved elongation, and a synergistic effect was observed with their combination.

Llegir més Ocultarpp. 456

ISSN: 2076-3417 -

Bondades y retos en el uso de las botellas de plástico para el envasado del agua (cap.)

Gil Castell, Óscar ; Badia Valiente, José David.

València: Universitat de València , 2024. LlibreMás claro, agua. Guía para un uso del agua más saludable y sostenible. Num.Col·lecció PUV - Publicacions Universitat de València

El grupo de investigación en materiales y sostenibilidad (MATS) de la Universitat de València ha colaborado en el reciente libro "Más Claro, Agua: Guía para un uso del agua más saludable y sostenible", editado por la Universitat de València e impulsado por la Cátedra de Cooperación y Desarrollo Sostenible y el Vicerrectorado de Sostenibilidad, Cooperación y Vida Saludable de la misma universidad, con el apoyo de la Generalitat Valenciana. En este contexto, Óscar Gil Castell y José David Badia Valiente han co-escrito el capítulo titulado "Bondades y retos en el uso de las botellas de plástico para el envasado del agua", en el que abordan una problemática de gran relevancia social y...

El grupo de investigación en materiales y sostenibilidad (MATS) de la Universitat de València ha colaborado en el reciente libro "Más Claro, Agua: Guía para un uso del agua más saludable y sostenible", editado por la Universitat de València e impulsado por la Cátedra de Cooperación y Desarrollo Sostenible y el Vicerrectorado de Sostenibilidad, Cooperación y Vida Saludable de la misma universidad, con el apoyo de la Generalitat Valenciana. En este contexto, Óscar Gil Castell y José David Badia Valiente han co-escrito el capítulo titulado "Bondades y retos en el uso de las botellas de plástico para el envasado del agua", en el que abordan una problemática de gran relevancia social y ambiental: el uso de botellas de plástico para el envasado de agua.

Llegir més OcultarEl capítulo examina los beneficios del uso de botellas plásticas en términos de accesibilidad y conveniencia, pero también discute los principales retos asociados a este material, como su impacto ambiental y las implicaciones para la sostenibilidad. Además, el texto se enmarca dentro de un libro que analiza el agua desde diversas perspectivas, empezando por sus propiedades y ciclo natural, la relación entre el agua y la salud humana, y los desafíos del consumo de agua embotellada, con especial énfasis en la huella ambiental de los plásticos.

Este libro, dividido en cuatro secciones principales, también propone estrategias para reducir el consumo de agua en el hogar y resalta la necesidad de una educación integral sobre la gestión sostenible del agua, así como la implementación de políticas públicas que promuevan un uso responsable de este recurso esencial.

- Título largo: Análisis de los beneficios y desafíos en el uso de botellas de plástico para el envasado de agua en un nuevo capítulo de libro sobre sostenibilidad

- Título corto: Desafíos del uso de botellas de plástico para el agua

-

Mechanism and performance of the hydrolytic chemical recycling of polylactide catalyzed by the protic ionic liquid 2-HEAA

A. Cháfer, O. Gil-Castell, A. Björling, R. Ballesteros-Garrido, J.P.Cerisuelo-Ferriols, J.D.Badia

(2024). ArticleResources, Conservation and Recycling. Num.Volume 210, November 2024, 107826

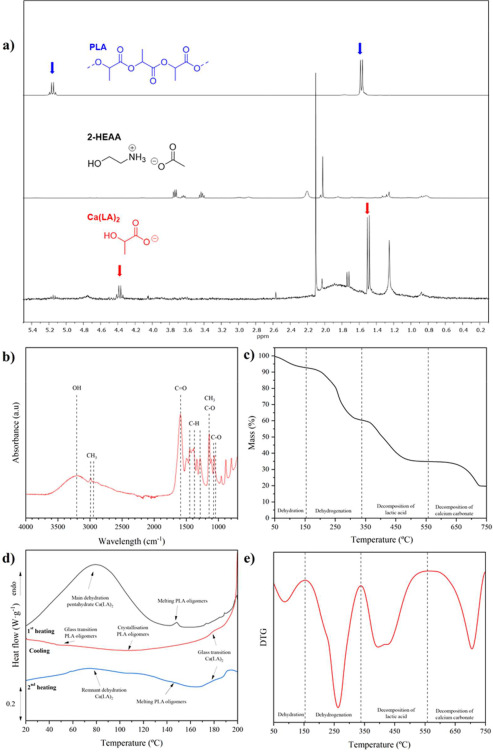

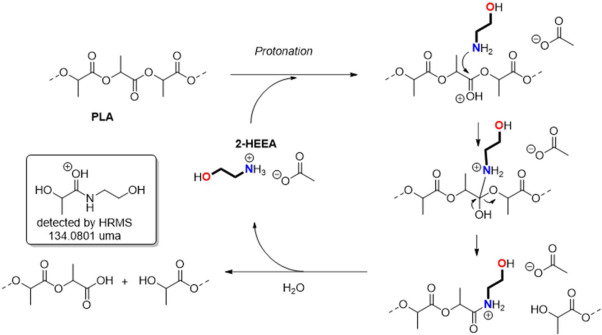

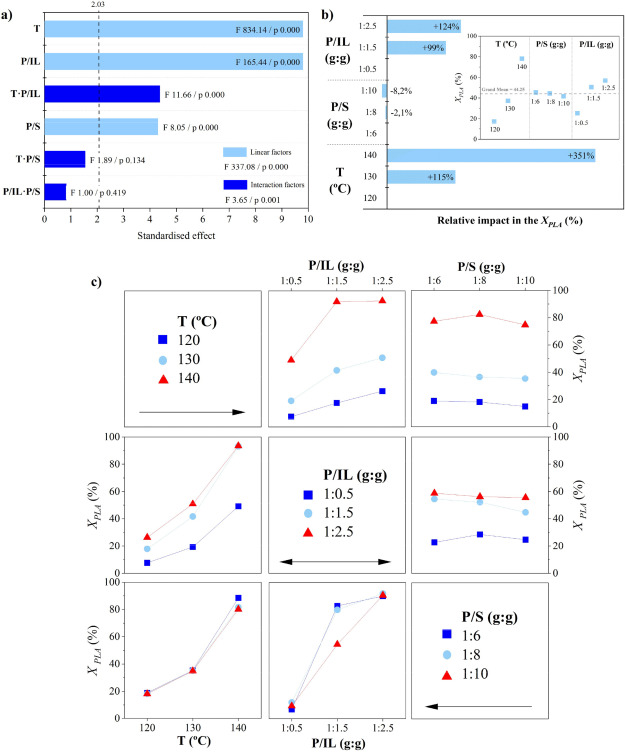

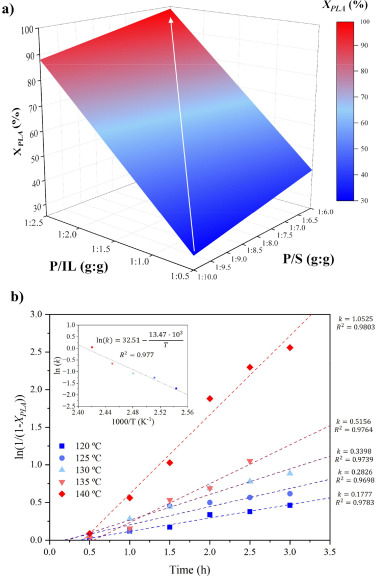

The hydrolytic chemical recycling of polylactide (PLA) aided by the protic ionic liquid 2-hydroxyethyl ammonium acetate (2-HEAA) as a homogeneous catalytic co-solvent was evaluated. In terms of maximization, temperature emerged as the most significant factor, being milder compared to that applied with other catalysts, resulting in potential energy savings. From a cost-efficiency perspective, employing a high solvent proportion was deemed unnecessary, thereby reducing reagent consumption. A higher proportion of ionic liquid leads to higher conversions, which could be trace-free recovered and reused in subsequent recycling steps. The best reaction triplet was a temperature of 140 °C, a mass...

The hydrolytic chemical recycling of polylactide (PLA) aided by the protic ionic liquid 2-hydroxyethyl ammonium acetate (2-HEAA) as a homogeneous catalytic co-solvent was evaluated. In terms of maximization, temperature emerged as the most significant factor, being milder compared to that applied with other catalysts, resulting in potential energy savings. From a cost-efficiency perspective, employing a high solvent proportion was deemed unnecessary, thereby reducing reagent consumption. A higher proportion of ionic liquid leads to higher conversions, which could be trace-free recovered and reused in subsequent recycling steps. The best reaction triplet was a temperature of 140 °C, a mass ratio between PLA and water of 1:6, and a mass ratio between PLA and 2-HEAA of 1:2.5, enhancing the efficiency of PLA conversion under a waste-to-gate circular model in the chemical valorization industry. Thermal kinetics explained by a first-order model, show an apparent activation energy of 112.3 kJ·mol-1, which is lower compared to other ionic liquids.

Llegir més OcultarKeywords: Chemical valorization; Hydrolysis; Polylactide (PLA); Protic ionic liquid (PIL); 2-hydroxyethyl ammonium acetate (2-HEAA); MechanismsKinetics

DOI: 10.1016/j.resconrec.2024.107826 -

Factorial Analysis and Thermal Kinetics of Chemical Recycling of Poly(ethylene terephthalate) Aided by Neoteric Imidazolium-Based Ionic Liquids

Oscar Gil-Castel, Ramón Jiménez-Robles, Alejandro Gálvez-Subiela, Gorka Marco-Velasco, M. Pilar Cumplido, Laia Martín-Pérez, Amparo Cháfer, Jose D. Badia.

(2024). ArticlePolymers. Num.16, 2451.

Poly(ethylene terephthalate) (PET) waste accumulation poses significant environmental challenges due to its persistent nature and current management limitations. This study explores the effectiveness of imidazolium-based neoteric solvents [Emim][OAc] and [Bmim][OAc] as catalytic co-solvents in the glycolysis of PET with ethylene glycol (EG). Reaction thermal kinetics showed that both ionic liquids (ILs) significantly enhanced the depolymerization rate of PET compared to traditional methods. The use of [Emim][OAc] offered a lower activation energy of 88.69 kJ·mol−1, thus making the process more energy-efficient. The contribution of key process parameters, including temperature (T),...

Poly(ethylene terephthalate) (PET) waste accumulation poses significant environmental challenges due to its persistent nature and current management limitations. This study explores the effectiveness of imidazolium-based neoteric solvents [Emim][OAc] and [Bmim][OAc] as catalytic co-solvents in the glycolysis of PET with ethylene glycol (EG). Reaction thermal kinetics showed that both ionic liquids (ILs) significantly enhanced the depolymerization rate of PET compared to traditional methods. The use of [Emim][OAc] offered a lower activation energy of 88.69 kJ·mol−1, thus making the process more energy-efficient. The contribution of key process parameters, including temperature (T), plastic-to-ionic liquid (P/IL) mass ratio, and plastic-to-solvent (P/S) mass ratio, were evaluated by means of a factorial analysis and optimized to achieve the maximum PET conversion for both neoteric solvents. The relevance sequence for both ionic liquids involved the linear factors T and P/S, followed by the interaction factors T×P/S and T×P/IL, with P/IL being the less significant parameter. The optimal conditions, with a predicted conversion of 100%, involved a temperature of 190 °C, with a P/IL of 1:1 and a P/S of 1:2.5, regardless of the IL used as the catalytic co-solvent.

Llegir més OcultarKeywords: plastic waste; valorization; chemical recycling; glycolysis; poly(ethylene terephthalate) (PET); neoteric solvents; ionic liquid.

Chicago/Turabian Style

Gil-Castell, Oscar, Ramón Jiménez-Robles, Alejandro Gálvez-Subiela, Gorka Marco-Velasco, M. Pilar Cumplido, Laia Martín-Pérez, Amparo Cháfer, and Jose D. Badia. 2024. "Factorial Analysis and Thermal Kinetics of Chemical Recycling of Poly(ethylene terephthalate) Aided by Neoteric Imidazolium-Based Ionic Liquids" Polymers 16, no. 17: 2451. https://doi.org/10.3390/polym16172451

[Llegir més] [Ocultar] DOI: 10.3390/polym16172451