Valencia, 26th September 2023

After two years of hard-working and collaboration with the partnership between Ford España S.A, Intelligent Data Analysis Laboratiry (IDAL), and NUTAI S.L, as coordinator, the "MAPl-iA" project: Industry processes advancee monitoring through Artificial Intelligence" A part from the main partnership, the project counted with the collaboration of the Automatics and Industrial Informatics Rsearch Institute (AI2), from the Universitat Politècnica de València (UPV). This initiative, financed through the fund programme in matters of strengthening and develpment of the Innovative Valencian System for the improvement of the productive model for the excercises 2021 to 2023 for the Innovation Valencian Agency (AVI) inside the frame of the FEDER Comunitat Valenciana Programme 2014-2020 (contract file number: INNEST/2021/362), has achived significat advances on the industrial monitoring and the predictive maintenance.

A project promoted by the Necesidad de Eficiencia

In an exponential grwoth context in the implementation of robots in the production plant in diverse industrial sectors, controlling maintenance costs has become crirtical to maintain competition. It is precisely for this reason that in this enviroment where "MAPL-iA" project main goal has been to develop an acquisition system of IoT data capable of predicting failure in industrial components using advanced techniques of Artificial Intelligence.

The importance of the project comes from the necessity of avoiding interruptions on production due to failures, which can cause great economic loss, and in minimising any costs associated with preventive changes of spares. The optimum point between these two sides is what makes it possible to achieve predictive maintenance, an strategy that minimises stopping times, optimises resources and, lastly, it increases productivity.

Transforming Industrial Monitoring

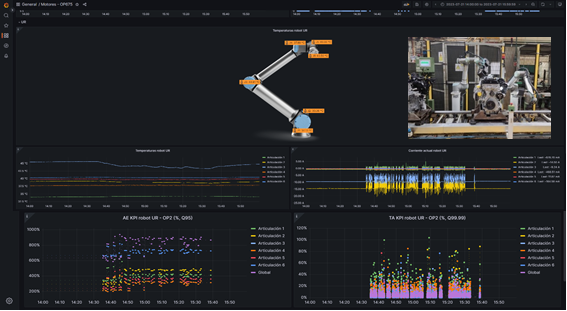

During the project, many significant advances were achieved, including the creation of an IoT modular device capable of compiling data from diverse sources, the elaboration of multivariable models to detect anomalies in temporal data series through a combination of statistic and algorithmic methods of Deep Learning, the definition of indicators is key on the performance (KPI's) to evaluate the industrial equipment’s health, the design of a multiclient platform based on Grafana that allows to visualise variables, states and KPI's, as well as anticipate anomalies as is shown in the figure. Finally, as last award, they have achieved to implement the project in the motor and bodywork plants of Ford in Almussafes, rigorously obeying with the security normative. These achievements are fundamental in the advance of industrial monitoring and predictive maintenance inside the factory.

The Industry of the Present and the Future

The Motors Plant was the main scenery of development and proof the project MAPl-iA with Ford Spain as soliciting company. The project initially focused in industrial and collaborative robots for tests, studies, use cases and validations. However, the possibility of amplifying its reach to other use cases is considered if its benefit and necessity is proved.

The success of the project MAPl-iA is a milestone in industrial monitoring and the application of Artificial Intelligence in the FORD factory. It represents a relevant example of collaboration between academic institutions, innovative companies and leaders of the industry, leading the way towards a futura where efficiency and quality take a central place in industrial production.

This pioneer project has established a solid precedent for the continuous improvement in monitoring industrial processes and the adoption of advanced technologies. With its successful conclusion, it opens the door to a future where Artificial Intelligence transforms the way of managing and supervising industrial operations.