- Universitat de València

- Garrido Blay, Maria Dolores

- PI-Invest Formacio Atraccio Talent

- Amoros Del Toro, Pedro Jose

- PDI-Catedratic/a d'Universitat

- El Haskouri Bennagi, Jamal

- PDI-Titular d'Universitat

- Ros Lis, Jose Vicente

- PDI-Catedratic/a d'Universitat

- Secretari/a d' Institut Universitari

- José Francisco Serrano Claumarchirant

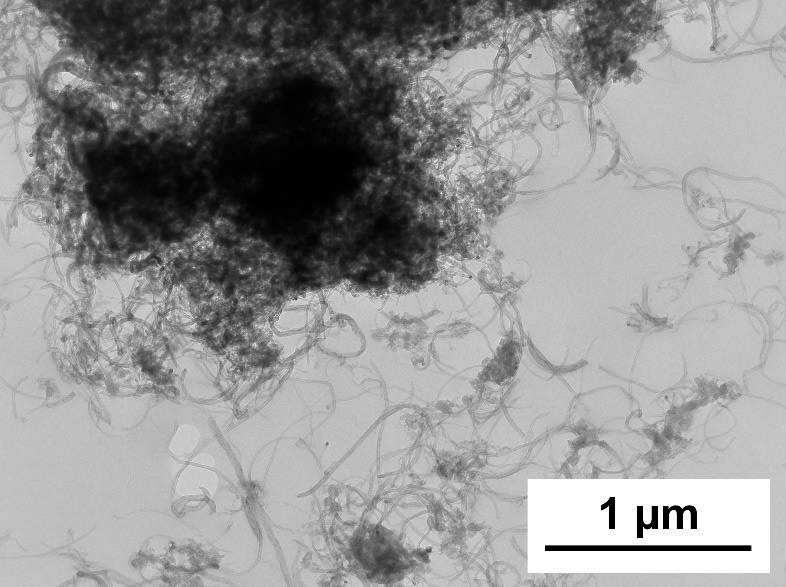

It is currently quite difficult to obtain a good homogeneous coating on the surface of carbon nanotubes (CNTs) with mesoporous silica due to issues with their dispersal prior to synthesis given that they aggregate easily. In most cases, ultrasound is used for long periods of time in order to obtain a better dispersal of the carbon nanotubes. Oxidising acid treatments are also used to functionalise the carbon nanotube surface and thus improve its dispersibility, but this does not eliminate the need to use ultrasound for long periods of time.

We can find very simple syntheses, but the result is not at all homogeneous, and a composite with a homogeneous coating and the correct morphology is not obtained.

Researchers at the Universitat de València have developed a new process for obtaining porous silica in the form of a nanocylinder. Such a nanocylinder may be empty or may include carbon nanotubes inside. Its synthesis is easy and fast to perform, improving the technique, as it no longer requires the use of ultrasound and reduces the time needed to obtain the materials. Furthermore, this technique has managed to completely coat the carbon nanotubes. The strategy used allows this to be the only product resulting from the synthesis. The research features the originality of using a mechanochemical synthesis stage, and the material obtained is homogeneous and the silica coating is uniform.

The present invention can obtain two types of materials: composites based on mesoporous silica nanocylinders with carbon nanotubes inside them or mesoporous silica nanomaterials containing very long cylindrical pores. Empty nanocylinders can be used in catalysis or controlled release in industrial processes, sensors or nanomedicine. Composite materials, such as carbon nanotubes, facilitate an increase in the number of applications in the above fields as well as other applications, such as electronics or telecommunications.

The described process presents the following advantages:

- Speed: Reduce the time needed to prepare the materials.

- High level of homogeneity of obtained material.

- Originality and uniformity in the resulting product.

- Patent applied

Blasco Ibáñez Campus

C/ Amadeu de Savoia, 4

46010 València (València)