MATS holds its fifth Seminar on "Design of Polymeric membranes for environmental technologies".

The MATS team is progressing in the development of polymeric membranes for decarbonisation processes of both liquid and gaseous effluents. To this day, they have been applying three different methodologies for the production of membranes with specific properties: electrospinning, supported liquid membranes and incorporation of pore formers in the initial formulation of the flat sheet membranes.

These investigations are developed within the framework of the projects MethBrane and Carbonbrane, both funded by the Spanish State Research Agency, co-directed by the researchers Marta Izquierdo and José Badia. In this way, in the seminar “V. Novel methodologies for tailoring PVDF membranes with improved properties for decarbonisation technologies”, that took place on 08/07/2024, the various researchers involved in these projects have presented the progress made in these investigations:

Alejandro Galvéz, has presented his work “Estudio de aditivos convencionales y deep eutectic solvents en la preparación de membranas planas”. Given the potential that the DES have as additives, pore formers and even solvents in the preparation of membranes, Alejandro has prepared PVDF membranes using the usual pore formers, Polyethylene glycol and glycerol, and also DES based in these compounds, aiming to evaluate the applicability of these new additives. As a result, Alejandro has proven that it is possible to obtain thinner membranes with a higher contact angle and close to 150º while using DES. This would help matter transfer in gaseous-liquid applications, such as the recovery of dissolved methane of anaerobic effluents.

Gorka Marco has presented his work “Evaluation of CO2 separation performance of NTf2-based supported ionic liquid membranes”. In it, he has developed PVDF supported liquid membranes with ionic liquids based in imidalozium cation and whose anion has a fluorinated base. Results showed that the permeability of CO2 increased significantly while the length of the cation alkyl chain decreased, reaching values down to 260 barrer. This also incremented the selectivity of the CO2 with respect to CH4 and N2, which demonstrates its potential application to CO2 capture processes, treatment of combustion gases and biogas enrichment.

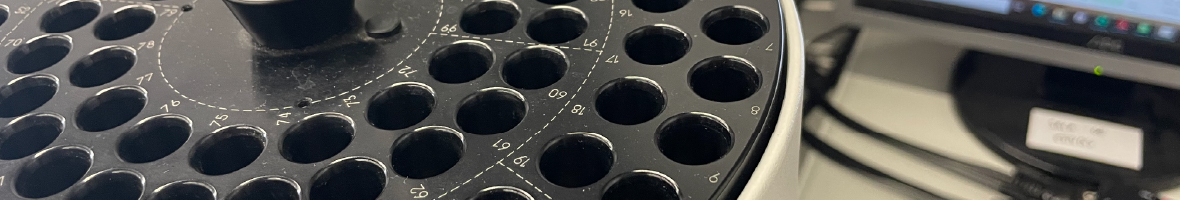

Félix Montero presented his work “PVDF electrospun nanofiber membrane integrity enhancement: Hot-pressing study and porometry measurements”. In this study, he has evaluated the process of thermic pressing on different conditions of PVDF membranes obtained by electrospinning. The results showed that the dimensions of the pores decreased considerably when incrementing the pressing temperature, reaching sizes lower to 140 nm. In conclusion, this work shows the possibility of adjusting the size of the pores in membranes electrospinned by thermic pressing, which would allow to use these membranes in a great variety of applications.