- Universitat de València

- Universidad Autónoma de Madrid

- IMDEA Nanociencia

- Ribera Hermano, Antonio Luis

- PDI-Titular d'Universitat

- Coronado Miralles, Eugenio

- PDI-Catedratic/a d'Universitat

- Director/a Titulacio Master Oficial

- Director/a d' Institut Universitari

- Abellan Saez, Gonzalo

- PDI-Titular d'Universitat

- Félix Zamora Abanades

- Rubén Mas Ballesté

- David Rodriguez San Miguel

The supercapacitors have drawn great attention in the industry as energy storage devices because of their high performance, in terms of reversibility, life cycles and high energy and power densities. The proper selection of electrodes is critical in this type of device, and the selected material must have high specific surface area, accurate pore size distributions, thermal stability and stable electrochemical behaviour. In this context, graphene, and especially the highly corrugated porous graphene is an exceptional candidate. Currently this type of graphene is obtained, for example, by procedures using MgO templates, graphene oxide cooling with liquid nitrogen, or a combined method of ion exchange and activation with NaOH. These processes are considered expensive and complex and, therefore, there is a growing interest in having scalable, cost-effective and simple synthetic methods for their industrial implementation.

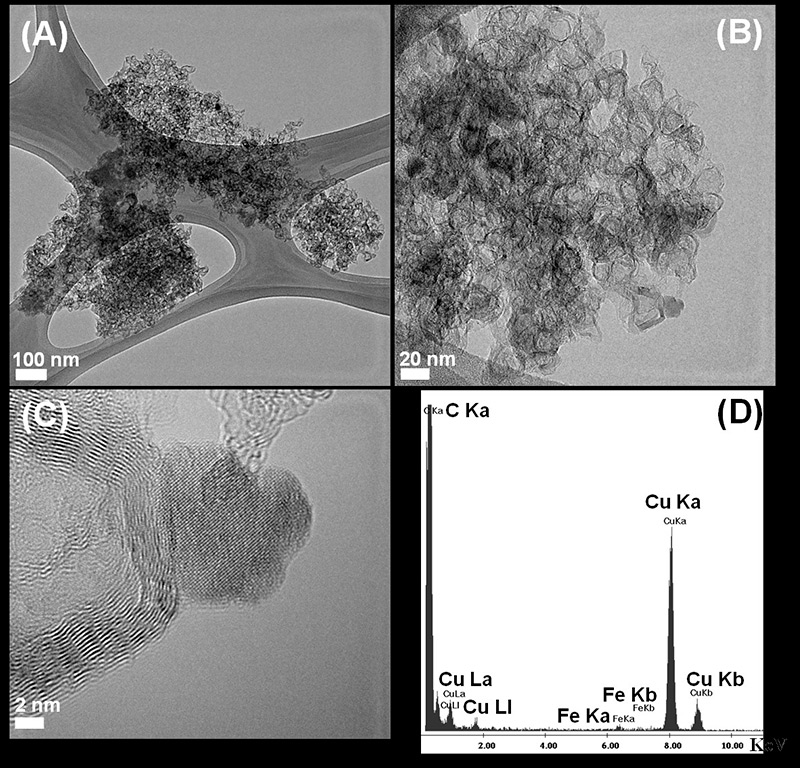

Researchers from University of Valencia, IMDEA Nanoscience and Autonomous University of Madrid have developed a new method for synthesizing highly corrugated porous graphene with excellent supercapacitive properties. The method consists of calcination at moderate temperatures (less than 1000°C) of COF materials ("Covalent Organic Frameworks") with adsorbed metals.

The effectiveness of the obtained graphene supercapacitive electrode, which exceeds the effectiveness of any related carbonaceous material, is caused by its high surface area and uniform pore size distribution. The structure, morphology and configuration of the precursor (COF type) promotes the generation of hierarchical porosity in the final material not needing to use MgO templates or ion exchange resins and NaOH. This method allows obtaining porous graphene in one step, without any problematic reduction step as in the case of the procedure using graphene oxide as precursor. The developed method also allows the incorporation of heteroatoms, such as nitrogen, in the graphene structure.

Graphene has many applications in materials science, electronics and nanotechnology, and in this case, particularly highlights the use of the obtained graphene in the manufacture of supercapacitors. Supercapacitors are mainly used for energy storage: "energy smoothing" and momentary-load devices, KERS devices used in vehicles, replacing batteries for specific cases, smaller applications like home solar energy systems, etc.

The developed method for graphene production has the following advantages:

- Low cost: chemical process of a single step with a single precursor, at low temperature, and using available, non-polluting and economical materials.

- Good properties of the obtained graphene: excellent textural and conductivity properties and stability and mechanical resistance from the point of view of their possible industrial processing for various applications.

- Supercapacitor application: suitable properties for use in the supercapacitors electrodes.

- Patent granted

Blasco Ibáñez Campus

C/ Amadeu de Savoia, 4

46010 València (València)